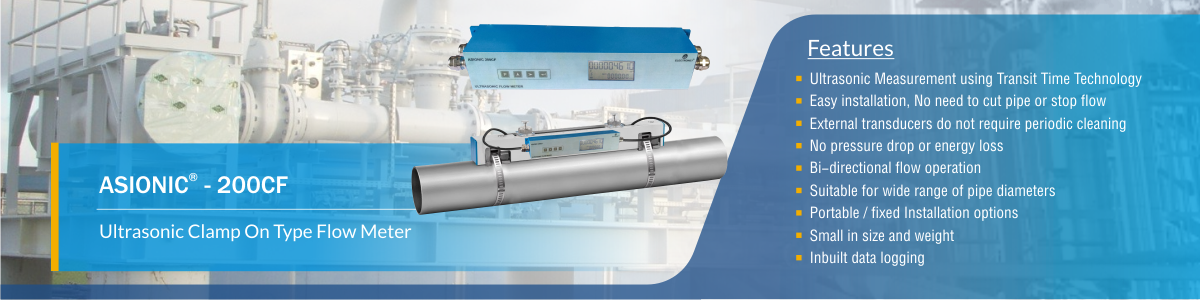

ASIONIC® - 200CF : Ultrasonic Clamp On Type Flow Meter

Working Principle

An ultrasonic flow meter is a type of flow meter that measures the velocity of a fluid with ultrasound to calculate volume flow. Using ultrasonic transducers, the flow meter can measure the average velocity along the path of an emitted beam of ultrasound, by averaging the difference in measured transit time between the pulses of ultrasound propagating into and against the direction of the flow or by measuring the frequency shift from the Doppler effect.

Ultrasonic flow meters are affected by the acoustic properties of the fluid and can be impacted by temperature, density, viscosity and suspended particulates depending on the exact flow meter. They vary greatly in purchase price but are often inexpensive to use and maintain because they do not use moving parts, unlike mechanical flow meters.

Product Description

Electronet series ASIONIC® - 200CF are Clamp-On Ultrasonic flow meters measure liquids in industrial applications. Because the sensor is clamped on to the outside of the pipe, it is immune to the process compatibility concerns of an in-line flow metering technology.

ASIONIC® - 200CF operates using transit time measurement. By measuring the time it takes for asonic signal to travel a known distance with the flow stream and another signal travelling against the flow stream, it determines the velocity of the fluid being measured. With the sonic properties of the fluid and the pipe material factored in, users get an extremely repeatable accuracy on the volumetric flow rate being measured. Because the transmitter can process the signal of one or two sensors, it ensures additional economy and the ability to compare or contrast two flow streams, if required.

The product is ideal for users looking for a process measurement device that is easy to install and can maintain flow measurement for clean liquids. ASIONIC� - 200CF clamp-on ultrasonic flow meters can be installed without stopping the process or having cut into the pipe line. It is ideal for process measurement in applications where users previously had not installed an in-line flow meter and for applications where large line sizes or exotic materials are required for in-line measurement technologies.